800.959.7841

Quick Custom Headers and Junctions

Check Standard Product Inventory, View Pricing, 3D Models

Daman Products now offers thermal deburring services for parts up to 10"x11"x22" for your standard and custom manifold projects. Invisible burrs, or internal burrs, cannot be seen by the human eye without expensive, high-power visual technology.

THERMAL DEBURRING

The Thermal Deburring Process

The process of thermal deburring involves parts being placed in a contained chamber where a mixture of fuel, gas and oxygen combine with temperatures of 2,500 to 3,300 degrees.

This extremely hot mixture completely covers the parts, exposing them to a combustion process that incinerates and removes all internal and external extraneous and micro-sized particles and burrs. They are usually removed after the first 30 seconds.

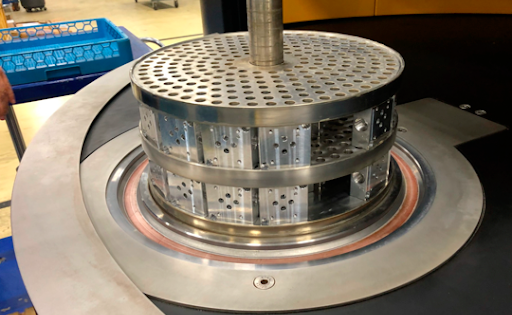

Daman's Thermal Deburring Machine

What Is A Thread Burr?

One of the most prevalent examples of burrs are thread burrs, also called string burrs. These are human hair-sized strings of aluminum which are buried within the root and crest of a threaded port or cavity. These strings cannot be detected by the human eye and often show themselves after a fitting or valve is screwed into the port then removed, exposing the thread burr. Thermal deburring removes all of these annoying burrs to ensure your manifolds are 100% free of burr contamination.

Before Thermal Deburring

Exposed thread burrs

.png)

After Thermal Deburring

No exposed thread burrs

Why Choose Thermal Deburring?

The thermal deburring process replaces manual intense deburring attempts which create employee stress and introduce the potential for human error.

The benefits of Daman’s new thermal deburring process include a cleaner, safer work environment for our employees, while offering customers a complete removal of particles with less time energy than our prior manual process.

This refines our overall production efficiency, improves throughput, and provides our distributors superior quality products absolutely free of metal burr contamination.

Thermal Deburring Applications

Thermal deburring can be applied to all hydraulic manifold applications including automotive, aerospace, power, energy and medical industries. Daman Products continues to explore opportunities to apply thermal deburring advancements to nontraditional fluid power markets as well.

For more information on Daman's thermal deburring capabilities, contact our Distributor Services Team at quotes@daman.com or by giving us a call at 1.800.959-7841.